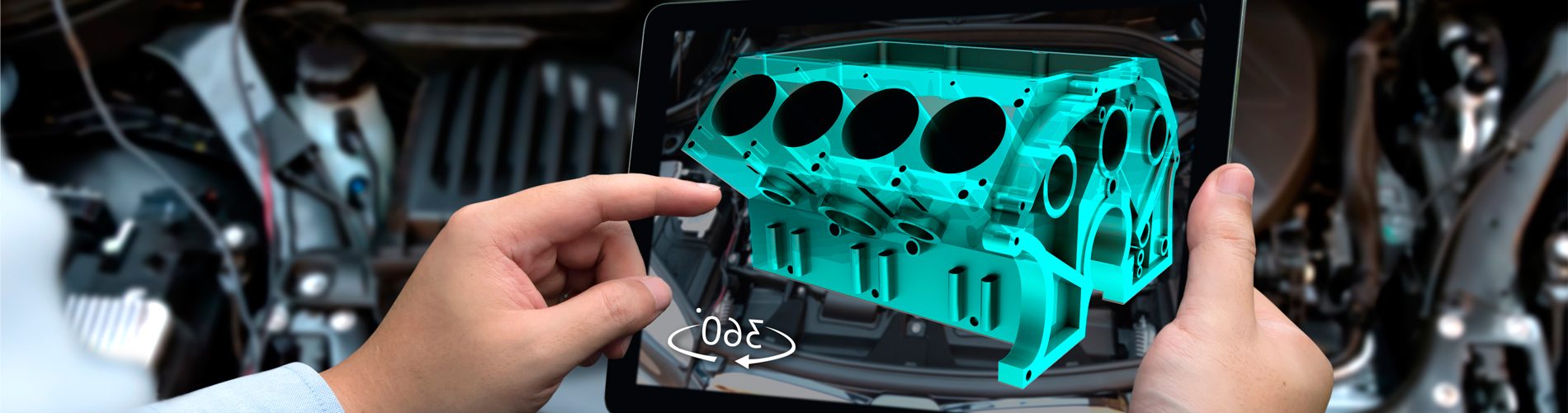

Due to its rapid technological advancement, Augmented Reality in manufacturing is a perfect fit. It was a hot trend long ago and it has reignited.

Assembly line, staff training, collaborative design, quality assurance, and maintenance: everything can be—and is—better with AR. Growing awareness and appreciation of AR’s value accelerates. There are use cases where Augmented Reality applications help boost—and simplify—workflow ensuring less time is spent from idea through prototyping to construction and finished product.

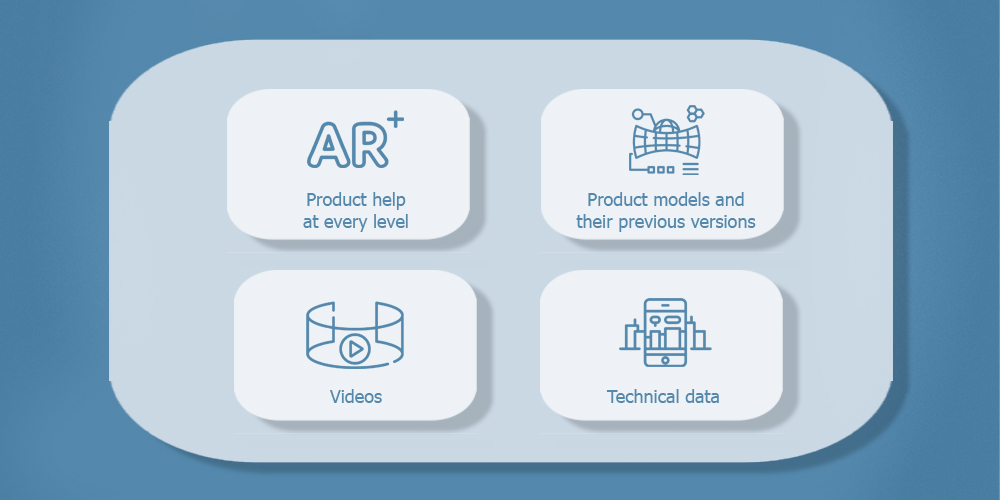

AR visualizes everything:

Visualizing everything makes it possible to determine the best option for a future prototype or to compare “what is” to “what should be” on the assembly line. In other words, you can show any detail right here, right now: a visual is worth at least 700 words of explanation.

Let’s see why and how it works.

Corporate giants, such as Ford, Volkswagen, Mercedes-Benz, and Boeing, have adopted Augmented Reality applications in both design and manufacturing. The list of companies using Augmented Reality keeps growing.

According to Deloitte Research, last year over 150 companies either experimented with or deployed AR/VR solutions.

The reasons to employ Augmented Reality in manufacturing and industry include:

Two advantages of Augmented Reality in manufacturing are expert support in assembly and maintenance or inspection in remote locations where workers need extra assistance or hands-free access to information.

Apart from inspection and troubleshooting, manufacturing uses Augmented Reality applications as the first step in high-risk training, augments the work of a distributed team and increases automation on the production line.

Here are just a few Augmented Reality examples in manufacturing to illustrate how AR can work. The list of apps is quite long; the list of needs—endless.

Augmented Reality is in huge demand by field workers providing features that other kinds of mobile apps lack.

Some manufacturers already tried Augmented Reality with less-than-stellar results. It is high time those early adopters give Augmented Reality a second life. Eli Whitney’s cotton gin is history; so, too, the Ford Model T—but not before making significant manufacturing marks on history.

Augmented Reality’s benefits are now immersive when it comes to decreasing operation time and/or boosting operational efficiency:

The boon of using Augmented Reality for manufacturing is restricted only by the limited number of enterprise-level Augmented Reality hardware suppliers and the price. However, there are practical apps right here, right now.

We should expect significant progress of AR hardware together with price decreases in the next few years. Be prepared for the increased demand when it arrives.

Leave a Reply